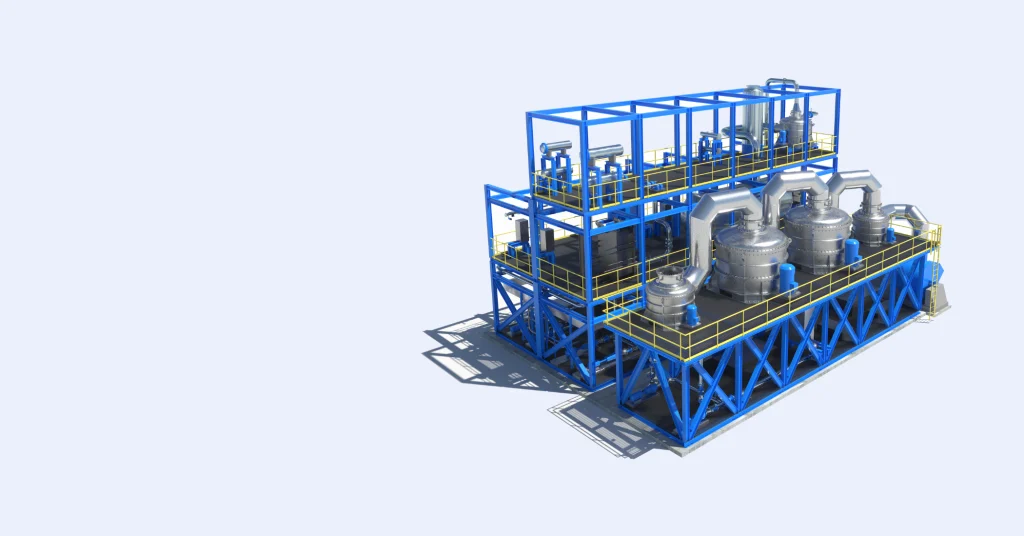

Carbon Clean has announced the Cyclone CC C1 series, marking the final stage of the technology’s commercialization.

Features:

With concentrations ranging from 3% to 20%, the Cyclone CC C1 series can absorb up to 100,000 tonnes of CO2 annually.

By being completely modular and columnless, the unit reduces height by 70% compared to traditional solutions. Rotating Packed Bed (RPB) technology, lowers the unit’s carbon footprint and the amount of steel needed by 35%.

Carbon Clean’s APBS-Cdrmax solvent outperforms industry standard, generating significant Opex savings with a five-fold longer lifespan. The product reduces corrosion by 20 times, decreases degradation by 10 times, and decreases energy demand by 10-25%.

The series offers a 50% smaller unit footprint and ten times smaller equipment sizes, reducing costs associated with transport, logistics, site preparation, and installation.

According to Carbon Clean, there is growing pressure on hard-to-abate industries to decarbonize as the 2030 deadline for a 45% reduction in global emissions approaches. Nevertheless, over half of industrial emitters do not have the necessary space to set up traditional carbon capture plants.

The company said that Cyclone CC C1 provides a practical and economical path to decarbonization, especially for small-to-midsize emitters, thanks to its space-efficient design.

Prateek Bumb, Co-founder and Chief Technology Officer, Carbon Clean, said, “… Repeatability is key to mass adoption, as demonstrated with solar panels and EV batteries. Carbon Clean is leading a similar transformation through eliminating the columns used in conventional carbon capture solutions. Cyclone CC’s ‘Lego-block’, ‘plug and play’ design makes it simple and cost-effective to install, making carbon capture financially and logistically viable to be deployed at scale.”